Fraunhofer Building Innovation Alliance presents its special show at BAU 2015

The way our cities grow and evolve will play a critical role in shaping developments in the 21st century, given that the race for an ecologically sustainable future is concentrated in these urban centers. “A constantly growing population and an increasing proportion of elderly people place new demands on the buildings and residential structures within our growing cities in terms of comfort, amenities, and security. At the same time, the resources for satisfying those demands are dwindling. We must ensure we are prepared for these challenges,” explains Prof. Klaus Sedlbauer, chairman of the Fraunhofer Building Innovation Alliance. But what exactly does this mean for cities in the future? The Fraunhofer Building Innovation Alliance and its 17 institute members are providing answers to this question at BAU 2015. Four major subject zones – construction materials, building systems, safety, and the “Morgenstadt (city of the future)” systems research – will showcase the technologies and a wide range of related software solutions at Fraunhofer’s special “Research City Workshop” show.

Construction materials

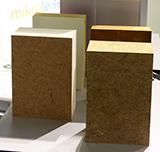

The quality of a building depends directly on the properties of the construction materials used. Resource efficient use of energy and materials as well as issues relating to the environmental and health impact of construction materials are key concerns of building research at Fraunhofer. A holistic approach to building requires the use of sustainable materials, ideally renewable ones. It stands to reason, then, that building research at Fraunhofer takes the properties of traditional construction materials that have been tried and tested in targeted further development and combines them with additional features. Apart from improving material properties, research focuses on how building materials can be made to perform certain functions and how they can best be recycled or reused.

In a joint research project with the industry, the Fraunhofer Institute for Mechanics of Materials IWM developed a composite system, which has excellent thermal insulation properties and can also absorb mechanical loads. Furthermore, it contains a high proportion of renewable raw materials. Using a core of "fireproof" petrochemical phenol foam and stabilizing top sheet fleeces made of flax and hemp it is a lightweight, durable insulation system. Due to the stabilizing effect of the surface layers, the sandwich can still take a load carrying function beyond the insulation. For perspective the classic masonry wall could be replaced by a bifunctional composite element with appropriate dimensioning.

Building systems

Prefabricated building components now play a major role in the industry. The benefits they offer are obvious: low development and manufacturing costs; straightforward repair and assembly processes; and increased flexibility, since reconfiguring a building’s various components adapts it to meet new requirements. Multifunctional construction components are therefore gaining ground: tomorrow’s façades will play a bigger role than just protecting against the elements – they will also feature shading or ventilating components, or even incorporate photovoltaic modules that help generate energy. A recent study promises huge growth potential in the leading market of energy efficiency, as flexible and versatile solutions will continue to play a dominant role in the areas of insulation, new buildings and renovation.

This aspect is being addressed by researchers at the Fraunhofer Institute for Solar Energy Systems ISE. They have developed special façade elements that make it possible to reposition insulation, heating and ventilation units as well as electrical and communications cables, and have even factored in the eventual retrofitting of these elements. This makes it possible to gradually replace existing building services with new components without having to significantly alter the fabric of the building or cause major inconvenience to the people living there. It also removes any obstacles to systematically retrofitting existing buildings with LowEx systems. At present, the Fraunhofer experts are working on various upgrade and customizing options for their façade systems to allow window, façade, climate technology and solar units to be installed independently of one another and in conjunction with traditional systems.

Safety

In a bid to provide buildings with more reliable protection against damage caused by short-duration dynamic events such as natural disasters or acts of terrorism, various Fraunhofer Institutes are developing a range of technologies for many different types of building. These technologies include innovative building materials, sensors and simulation tools. The aim is to combine safety issues with requirements relating to quality assurance, architectural design and building functionality. Interest is directed particularly at construction materials that demonstrate a high capacity to absorb energy, which would allow them to better dissipate sudden destructive stress loads. System solutions based on modular designs, which can be adapted easily to different areas of application, and integrated building systems with continuous monitoring capabilities in real time are further subjects of particular interest to safety.

For instance, scientists at the Fraunhofer Institute for High-Speed Dynamics, Ernst-Mach-Institut, EMI, are developing ultra-high-performance construction materials. One of the options they are investigating is natural-fiber-reinforced polymer concrete, an energy-absorbing material that guards against damage from explosions. It protects exterior walls from nearby detonations and ensures that construction components’ residual strength is maintained. Because this concrete can be made from renewable raw materials, its production also saves on resources. One of the major benefits is that it allows existing buildings to be easily retrofitted using cost-effective materials.

Short-duration dynamic effects are increasingly being taken into account during the planning stages of construction, particularly for high-rise building projects. Under Part 9 of the DIN 1055 standard, accidental actions are regulated only on an informative basis; assessment proposals are not incorporated. Fraunhofer EMI is therefore presenting appropriately designed materials and using its APOLLO blast simulator to demonstrate simulation tools at its special show.

Smart Cities

For industrialized societies, cities are the key to a sustainable future. The political and economic foundations we lay today will determine the quality of tomorrow’s ecosystems and whether we can safeguard and maintain our global resources. Designing sustainable cities requires technical, organizational and financial innovations. These are created when stakeholders collaborate across disciplines to bring creative approaches to new technologies. Fraunhofer’s “Morgenstadt (city of the future) initiative provides the space required to facilitate this kind of innovation. The Morgenstadt: City Insights innovation network is a subproject of the Fraunhofer initiative that has analyzed six of the world’s leading cities for systemic urban solutions since May 2012. The project team examined over 100 best practices for sustainable urban development, categorized into eight research sectors. This generated 50 innovative, pioneering ideas for individual projects in smaller industrial, municipal and research consortia. At the same time, Fraunhofer researchers are using the results of this analysis to develop a tool with which to analyze urban systems’ future sustainability performance.

Cities all over the world may be experiencing dynamic change, but below ground they are often inflexible and unchanging. In an effort to reduce the high costs of conventional water supply and drainage networks, scientists and engineers have developed DEUS 21, which stands for DEcentralised Urban infrastructure System. Funded to the tune of two million euros by the German Federal Ministry of Education and Research (BMBF), the project represents a form of water management by local communities that is unique in Germany. DEUS 21 is headed up by the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB in Stuttgart, and involves the collection and repurposing of rainwater. Rainwater is channeled into a central, modern membrane plant where it is processed to drinking water quality. This hygienic service water is then piped into households where residents can use it for showering, in their dishwashers and washing machines, to flush toilets or to water their gardens. The water has a very low mineral content, meaning there is no need to use decalcifying agents when heating water or fabric softener when washing laundry. With the DEUS 21 wastewater treatment system, wastewater components are also converted into biogas and the nutrients nitrogen and phosphorus extracted for use as fertilizer salts. The biogas supplies the plant with electricity and heat, and any excess electricity is fed into the public power grid. Wastewater is processed in such a way that virtually no sludge is produced.

Software

Experts expect that consistently applying Building Information Modeling Methods (BIM) will stimulate the competitiveness of the German construction and real estate industries. As part of its “Mittelstand-Digital” priority funding project, which aims to help SMEs make the most of the digital age, Germany’s Federal Ministry for Economic Affairs and Energy (BMWi) is now funding the BIMiD research project, in which a real construction project will serve as an example for demonstrating and evaluating BIM methods. BIMiD stands for BIM-Referenzobjekt in Deutschland (BIM reference object in Germany), and recently the construction project that will form the basis of the project was presented in Berlin. Chosen from among almost 100 candidates in a selection process spanning several months, the showcase project will be Volkswagen Financial Services AG’s new “House H” office building in Brunswick. Over the next two years it will be used as a model to demonstrate and scientifically evaluate idealized BIM processes. Everyone involved will work to a single data model throughout the life cycle of the construction project, ensuring the greatest possible efficiency and quality is achieved by virtue of a uniform planning process.

Last modified:

Fraunhofer Building Innovation Alliance

Fraunhofer Building Innovation Alliance